Tire Pressure Monitor Systems (TPMS)

Since September 2007, the United States Department of Transportation (DOT) National Highway Traffic Safety Administration has adopted a Federal Motor Vehicle Safety Standard that requires the installation of tire pressure monitoring systems (TPMS) that alert drivers when one or more tires become significantly under-inflated. The safety standard applies to vehicles with a gross vehicle weight rating of 10,000 pounds or less. Many vehicles produced earlier have TPMS also. This federal mandated safety standard is like the requirement that vehicles have seat belts, and from a legal standpoint, by-passing the TPMS system would be the equivalent of cutting your seat belts.

How Do Tire Pressure Monitoring Systems Work?

In most cars and light trucks, the mandated Tire Pressure Monitoring System comes in the form of an electronic sensor attached to the valve stem. The electronic sensor is battery powered and transmits the sensor ID and the tires inflation to a receiving antenna in the car. When the air pressure inside any of the tires drops 25% below the recommended cold tire inflation shown on the Vehicle Placard, a warning light on your dashboard will go on. The warning light will look like the figure on the right if a tire is underinflated, and the figure on the left if the system is malfunctioning.

Common TPMS Problems

When congress specified that car manufacturers were required to implement a low tire warning system, they didn’t specify exactly how it should be done. As a result, engineers at each car manufacturer came up with a wide range of warning systems. Some were pretty good. Others not so much. Over the last decade the problematic warning systems have been weeded out of the marketplace, but there are still a lot of cars on the road that have cranky TPMS systems and sensors. Here are a few of the common issues and concerns that drivers should be aware of regarding TPMS:

- The TPMS transmitter and receiver often do not communicate properly or are not relearned properly causing the TPMS light on your dash to give a false warning or to read improperly. This is especially common after tire rotations and other tire services.

- The metal valves found on many TPMS systems are frail and may easily crack or break off when putting air in the tire or removing the valve core.

- The valve cores and caps can become seized due to galvanic corrosion.

- The rubber gaskets become brittle and prone to air loss over time.

- The battery will eventually wear out, requiring replacement of the TPMS sensor as we cannot replace just the battery (In our experience, most batteries are lasting 5 to 7 years, so the first generation of TPMS equipped vehicles are now starting to have battery failures that light up the TPMS warning light on the dashboard).

Another point of interest, each TPMS sensor transmits a unique identifying number via radio waves to the cars receiver. Some folks say this federally mandated vehicle component creates a privacy concern that could allow Big Brother to track our movements. Personally, I think they give our government too much credit, but to allay the fears of the lunatic fringe, we put in new TPMS sensors every day and do not report the transmitter information to Big Brother.

TPMS Servicing Tips

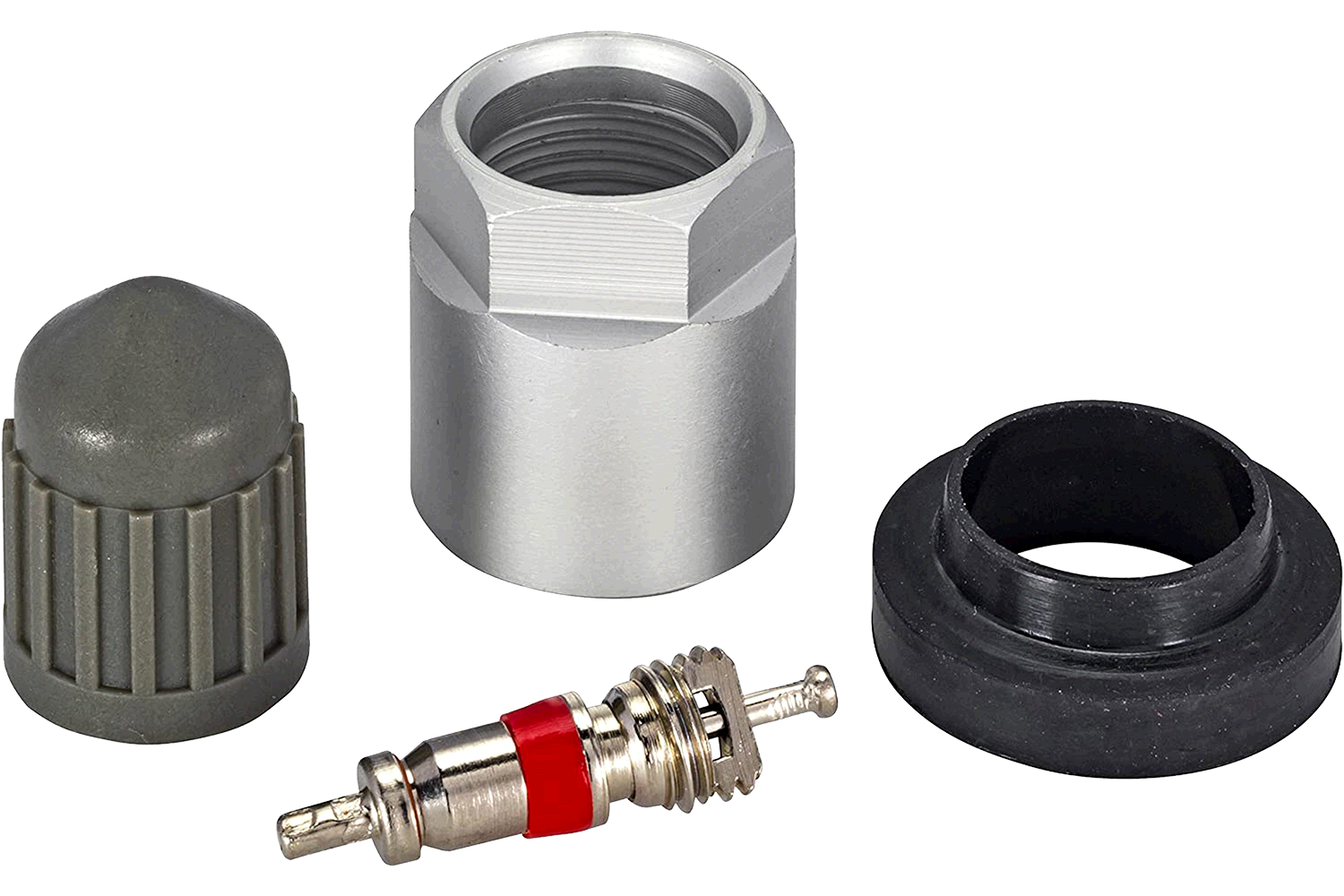

Each TPMS Sensor is made up of several components, including a nickel-plated valve core, a rubber grommet, a replacement valve cap with a grommet inside, and a locknut. We normally charge around ten dollars for these components and the labor to install them, and the standards of our industry say that the components should be replaced each time the tire is serviced to minimize the common TPMS problems discussed above.

But the reality is that replacing all these components sometimes creates more problems than it solves, as disassembly of the TPMS Sensor can sometimes end up damaging the valve, requiring its replacement. In practice, we allow our technicians some leeway in this matter. If, in our technician’s judgement, disassembly of the valve will cause irreparable damage to the sensor, we will give you the option of not replacing these components, with the understanding that the original components may fail later allowing air to escape from the tire.

TPMS Relearn Procedures

On many of today’s cars, the TPMS sensor transmits a unique identifier code which is mapped to the wheel location to which the TPMS Sensor is attached. For these vehicles, the dashboard will display which tire is underinflated. When a TPMS sensor is moved around on these types of vehicles when we rotate the tires, it may be necessary to help the vehicle “relearn” where the sensor has been moved to so that it will properly indicate which tire is underinflated. The relearn process also must be done when a new sensor is installed onto the vehicle. This process is another part of the TPMS world that is simple on some cars and challenging on others. If you have one of those “special” cars, please have patience with us. On some vehicles, the new TPMS sensor will awaken itself once the vehicle has been put into motion and it will sync up with the transmitter on its own after a bit of driving. Other vehicles require a technician to spend around 15 minutes using a special TPMS programming scan tool to reset the light. Some DIY folks have asked about buying their own TPMS programming scan tool, but when told that the tool runs $1200 on the low end, they happily pay us the $10 fee we charge for reprogramming the system and turning off the TPMS light on the dash.

Loading ...

Missing nap lines data / Error occured while getting the data.